WARNING: This product contains nicotine. Nicotine is an addictive chemical.

The vaping industry has grown exponentially in recent years, and the demand for high-quality vape products has increased significantly. With this increase in demand, it’s important for companies to ensure that their vape products meet the highest quality standards during research and development (R&D).

Quality control during R&D is critical to ensure that the final product is safe, effective, and meets the desired quality standards. In this article, we will discuss some of the key considerations for vape product quality control during R&D.

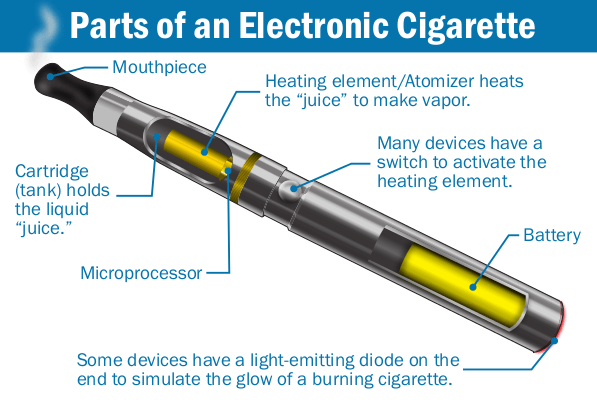

The materials used in vape products can have a significant impact on product quality. First of all, the materials should be harmless to customers. Furthermore, to ensure the effective functioning of vape products, the components should be of high quality and match well with each other.

Batteries

The battery is a crucial component of any vape product, and its quality and safety should be carefully considered during R&D.

Low-quality batteries can pose a significant risk of explosions and other safety hazards. High-quality batteries that are properly installed and have adequate protection mechanisms to prevent overcharging, overheating, and other potential safety issues not only can prevent the safety risks, but also allow you to have a long-lasting vaping experience without frequent recharging.

E-liquid

It’s essential to carefully evaluate the safety and efficacy of each ingredient used in e-liquid.

Low-quality e-liquid would contain flavorings that can cause respiratory issues and other health problems when inhaled and the impurities or contaminants in e-liquid could pose risks to the consumer. High-quality e-liquid is the key to having smooth hits. The flavorings used in e-liquids must be food-grade and safe for consumption. A good quality e-liquid should have a well-balanced flavor profile, allowing the user to enjoy the flavor without it being too overwhelming. The e-liquid should also work perfectly with the device

Cotton

Cotton is used as a wicking or store material in vape products, and its quality can affect the overall flavor and performance of the product.

Poor-quality cotton can affect the flavor, resulting in a burnt taste and reducing the lifespan of the coil. As such, it’s important to use high-quality cotton that is specifically designed for use in vape products to wick and store the e-liquid properly.

Mouthpiece

The mouthpiece is the part that the user inhales from, and its quality can affect the overall comfort and safety of the product.

Poor-quality mouthpieces can be uncomfortable to use and may transfer harmful chemical substances in your mouth. It’s essential to use high-quality food-grade and durable materials for the mouthpiece and ensure that it is properly installed and securely attached to the device.

PCBA Board

The PCBA board is the electronic circuit board that controls the functions of the vape product. Its quality and safety should be carefully considered during R&D.

Poor-quality PCBA boards can result in malfunctioning devices, potentially causing safety hazards such as overheating or explosions. It’s important to use high-quality PCBA boards that are specifically designed for use in vape products and to ensure that they are properly installed and function as intended.

The structural design of vape products plays a critical role in ensuring their quality and safety. Good structure design can give smooth hits and an enjoyable vaping experience, which is what makes the KEYSTONE vape products stand out in the crowd. Several design factors should be considered during R&D to ensure the vaping smooth.

Sealing

The sealing of vape products is crucial to prevent leakage of e-liquid, which can cause safety hazards and reduce the effectiveness of the product. During R&D, it’s essential to design the product with effective sealing mechanisms to prevent leakage and ensure that the product functions as intended. Proper sealing can also help to protect the product from outside elements, such as dust and moisture, which can affect its quality and lifespan.

The silicon components play a vital role in ensuring effective sealing. Silicone is a synthetic material that is highly resistant to heat and chemicals, making it ideal for use in vape product sealing. It is also highly flexible and can be molded into various shapes and sizes, making it suitable for use in different types of vape products.

During the R&D process, KEYSTONE VAPE conducts various tests to ensure that the silicone components used for sealing are of good quality and can withstand the heat and pressure generated during use. They also test the components to ensure that they are the correct size and shape for the device and can provide effective sealing.

Independent Air Passage

The air passage of vape products plays a critical role in ensuring that the user inhales the vaporized e-liquid effectively. Poorly designed air passages can cause issues such as reduced airflow, which can affect the overall flavor and effectiveness of the product. Additionally, poorly designed air passages can also cause safety hazards such as overheating and potential explosions.

During R&D, KEYSTONE VAPE designs the product with an independent air passage, which ensures that the vaping functions effectively. The independent air passage is built by sealing silicon, preventing the effects of airflow come from other sides. The air switch will sense the air precisely and be on as soon as you inhale so that the vaping hits would be quicker and smoother.

The match of e-liquid and device is also a critical factor in ensuring the overall quality and safety of vape products. The e-liquid must be compatible with the device, and its composition should not cause any safety hazards or damage to the device. Additionally, the device’s design should allow for effective vaporization of the e-liquid, ensuring that the user receives the desired amount of vapor and flavor.

During R&D, it’s essential to test the compatibility of different e-liquids with the device and to ensure that the device’s design is optimized for vaporizing the e-liquid effectively. Proper testing and analysis of the match of e-liquid and device can help to ensure that the product functions effectively and safely.

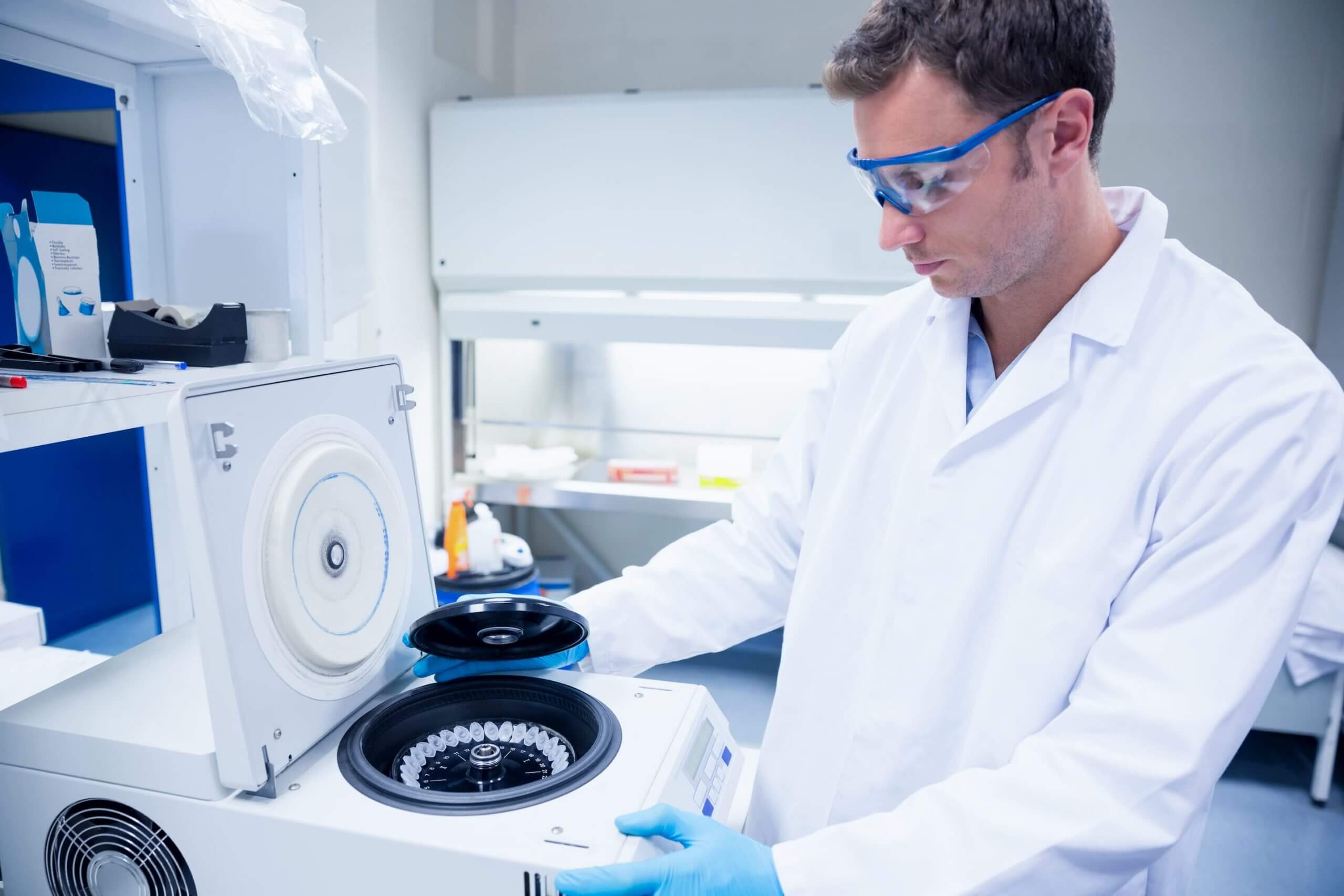

Testing and analysis are crucial aspects of vape product quality control during R&D. It’s essential to conduct extensive testing to ensure that the product is safe, effective, and meets the desired quality standards. Various types of testing can be conducted in different stages of R&D.

Envirotronics

During the R&D process, manufacturers conduct environmental testing to ensure that the vape product can withstand different environmental conditions and continue to function efficiently. Envirotronics involves testing the vape product’s performance and durability under various environmental conditions, including temperature, humidity, pressure, and vibration. Strict envirotronics are carried out on every single vape product developed by KEYSTONE to ensure efficient function under different conditions.

Temperature and humidity testing simulates different living conditions in different countries or areas around the world in different seasons. There are mainly 3 kinds of tests. One is high temperature and high humidity to see if the vape device can function efficiently under 60°C and 85% humidity. It stimulates the living conditions in tropical areas or other areas on summer days and the conditions when shipping by boat. One is the low temperature to simulate how the vape product works in cold countries. The testing temperature is usually -20°C. The other one is testing the vape product performance when the temperature changes, the temperature range is between 60°C and -20°C, which simulates the temperature changes outside and inside a room in winter in cold areas.

The vape product can only be regarded as qualified if all these tests are passed. Though vape products can work under different conditions, high or low temperatures or improper humidity would definitely affect the product function efficiency.

Vibration and pressure testing is also conducted to ensure that the vape product can withstand vibration, shock, and vacuum environment without malfunctioning or causing safety hazards for daily use and during shipping in different ways, such as by air. This is particularly important for portable vape products that are often carried around and can be subjected to bumps and shocks.

By conducting envirotronics testing during the R&D process, manufacturers can identify and address any issues with the vape product’s performance and durability under different environmental conditions. This helps to ensure that the product is safe, efficient, and reliable for users to use in different environments.

Emission Testing

Emission testing is a crucial part of vape product quality control during R&D. Emission testing involves analyzing the components of the vapor emitted by the vape product, including nicotine, flavorings, and other chemicals that may be present in the e-liquid, to ensure that they do not pose any health risks to users or those around them. By conducting emission testing during the R&D process, KEYSTONE can identify any potential health risks associated with the vape product and take steps to mitigate them.

KEYSTONE also test the vape product’s emission levels to ensure that they meet regulatory standards. In many countries, there are regulations that limit the number of certain components that can be present in the vapor emitted by vape products.

Other Testing

In addition to emission testing, manufacturers also conduct performance testing to ensure that the vape product functions efficiently and effectively. This includes testing the material, the chemical analyses, battery life, atomizer performance, puffs, e-liquid delivery system and etc.

The production process is another key consideration for vape product quality control during R&D. The production process should be designed to ensure consistency, quality, and safety of the final product. It’s essential to develop a process that is efficient, reliable, and can be replicated consistently to avoid inconsistencies in the final product.

All the important factors should be taken into consideration for vape product quality control during R&D to ensure that the product is safe, efficient, and effective for users to use. All these tests should be carried out precisely to ensure that the final product is of high quality and functions efficiently.

If you want to know more, please refer to this article:

https://keystonevape.com/best-vape/the-best-disposable-vapes-2024-you-cant-miss/