WARNING: This product contains nicotine. Nicotine is an addictive chemical.

Vape product manufacturing is a rapidly growing industry, with a wide variety of products and components available to consumers. To remain competitive in this market, it is essential to maximize efficiency in the manufacturing process. Strategies for maximizing efficiency are applied in all KEYSTONE vape product manufacturing activities.

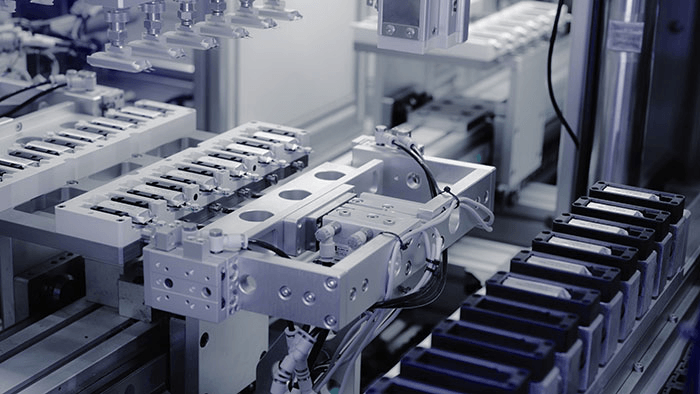

Automate Processes

Automating repetitive tasks can save time and improve accuracy. In vape product manufacturing, there are several tasks that can be automated, such as refilling e-liquid, labeling packaging, and packaging products. By using machines to perform these tasks, manufacturers can increase productivity and reduce the risk of human error.

Implement Lean Manufacturing

Lean manufacturing is a systematic approach to reducing waste and streamlining processes. In vape product manufacturing, this approach can help to minimize the time and resources required to produce products. By identifying inefficiencies and eliminating them, manufacturers can reduce costs, improve product quality, and increase customer satisfaction.

Use Quality Materials

Using high-quality materials can improve product consistency and reduce waste. When selecting materials, manufacturers should consider factors such as durability, purity, and compatibility with other components. By using quality materials, manufacturers can reduce the risk of defects, improve product performance, and increase customer loyalty.

Optimize Production Schedule

Developing an optimized production schedule can help to ensure that all processes are completed in a timely and efficient manner. This can be achieved by identifying bottlenecks in the process and adjusting schedules accordingly. By optimizing the production schedule, manufacturers can reduce lead times, improve delivery times, and increase customer satisfaction.

Train Staff

Well-trained staff can work more efficiently and make fewer mistakes. Providing training on the manufacturing process and safety procedures can help to improve productivity and reduce the risk of accidents. By investing in employee training, manufacturers can improve product quality, reduce waste, and increase profitability.

Conduct Regular Maintenance

Regularly maintaining equipment can help to prevent breakdowns and improve the longevity of machines. This can be achieved by developing a maintenance schedule and sticking to it. By conducting regular maintenance, manufacturers can reduce downtime, improve product quality, and increase productivity.

In conclusion, maximizing efficiency in vape product manufacturing is essential for remaining competitive in the industry. By implementing these strategies, vape product manufacturers can maximize efficiency, reduce waste, and improve product consistency, which can ultimately lead to increased profitability, which is why KEYSTONE VAPE can stay ahead of the competition and meet the growing demand for vape products.

If you want to know more, please refer to this article:

https://keystonevape.com/best-vape/the-best-disposable-vapes-2024-you-cant-miss/